Maximum productivity with imo rotary transfer machines

Rotary transfer machines are an important component of industrial production, as they enable high productivity. A key advantage of imo rotary transfer machines is that they offer high repeat accuracy and throughput rates. This leads to higher productivity and reduces production costs.

Another advantage of imo rotary transfer machines is their flexibility. The ability to easily adapt the machine to the requirements of the product means that it can be used for a wide range of products. This enables more efficient use of the machine and secures the acquisition costs.

Overall, imoberdorf rotary transfer machines offer high productivity, flexibility and reliability. They are therefore the right choice for industrial production.

imo-compact

Our imo-compact solution is extremely space-saving, ergonomic and efficient. Developed for complete series production with up to 8 standard machining stations (or up to 20 compact machining stations). The stations are equipped with our up to 4-axis machining units. A wide variety of spindle configurations (vertical/horizontal, parallel, offset), tool changers, (pneumatic) measuring mandrels and 3D measuring probes are available. Supplemented by our standard clamping systems, this results in a wide range of proven technology modules. The software modules we have been developing in-house for decades round off our expertise as a machine manufacturer.

Your advantages:

- The repeatability is ± 3 μm.

- Individual loading/unloading handling

- Individual complete solution

- Extremely space-saving

- Up to 8 processing stations possible

imo-smart

As the name suggests, imo-smart is our intelligent solution for the smart machining of complex customer workpieces for complete series production. With up to 12 machining stations, it offers the necessary machining versatility to manufacture workpieces according to customer requirements. The stations are equipped with our up to 4-axis machining units. A wide variety of spindle configurations (vertical/horizontal, parallel, offset), tool changers, (pneumatic) measuring mandrels and 3D measuring probes are available. Supplemented by our standard clamping systems, this results in a wide range of proven technology modules. The software modules we have been developing in-house for decades round off our expertise as a machine manufacturer.

Your advantages:

- Repeat accuracy is ± 3 μm

- Individual loading/unloading handling

- Individual complete solution

- Processing of small to large parts

- Up to 12 processing stations possible

imo-space

As the name suggests, imo-space offers a very large workspace. It can accommodate up to 16 machining stations with up to 45 or more spindles – the production potential is enormous.

The stations are equipped with our up to 4-axis machining units. A wide variety of spindle configurations (vertical/horizontal, parallel, offset), tool changers, (pneumatic) measuring mandrels and 3D measuring probes are available. Supplemented by our standard clamping systems, this results in a wide range of proven technology modules. The software modules we have been developing in-house for decades round off our expertise as a machine manufacturer.

Your advantages:

- Repeat accuracy is ± 3 μm

- Individual loading/unloading handling

- Individual complete solution

- Very large working area

- Up to 16 processing stations possible

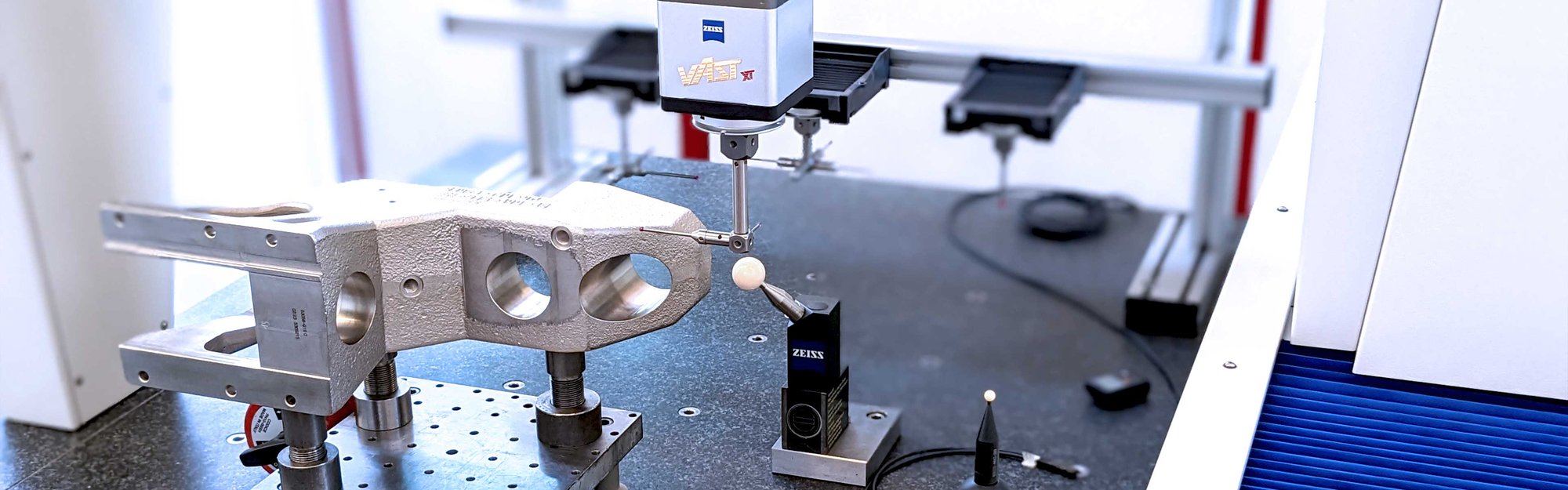

Our quality standards

Our quality standards are of utmost importance to us. We strive to meet the highest requirements in terms of materials, manufacturing technologies and processes to ensure that our products and services meet the highest quality standards. We are committed to ensuring that our customers are completely satisfied with our products and services and are constantly working to improve our quality processes.

News from our industry

Unmanned manufacturing is now a reality

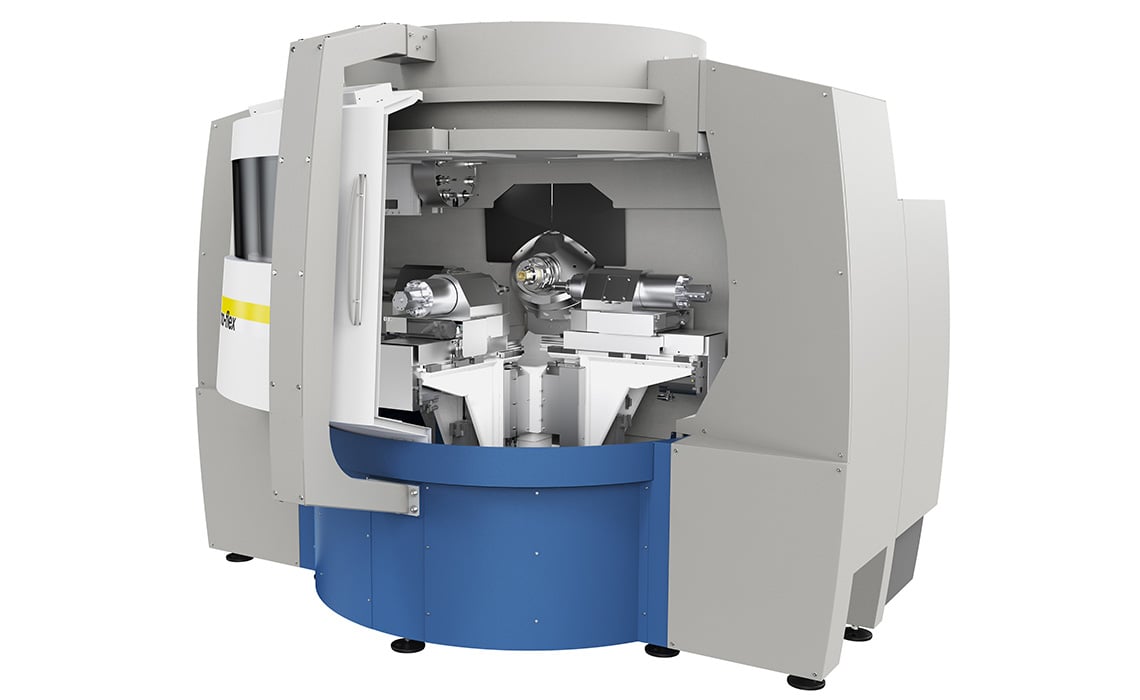

Our new flagship "imo-flex"

-1920x910-HG_Weiss-Banner-Haupseite_1140x700.jpg?width=1140&height=700&name=NEU_2023_01-(63043-821_Werkzeug_1)-1920x910-HG_Weiss-Banner-Haupseite_1140x700.jpg)

Flexible solutions with high accuracy and dynamics

You may also be interested in

Technologies

Discover what makes our systems special.

Industries

Discover the industries in which our systems are used for production.

About us

Discover what makes Imoberdorf Ltd special

Career

Discover the career opportunities we offer