Technological competence as a strategic advantage

The name imoberdorf stands for durable, quality machining systems that produce high-quality, small to medium-sized parts, in large quantities, extremely precisely and quickly. Our demand for perfection covers the entire production process. That is why we only use premium components in our systems.

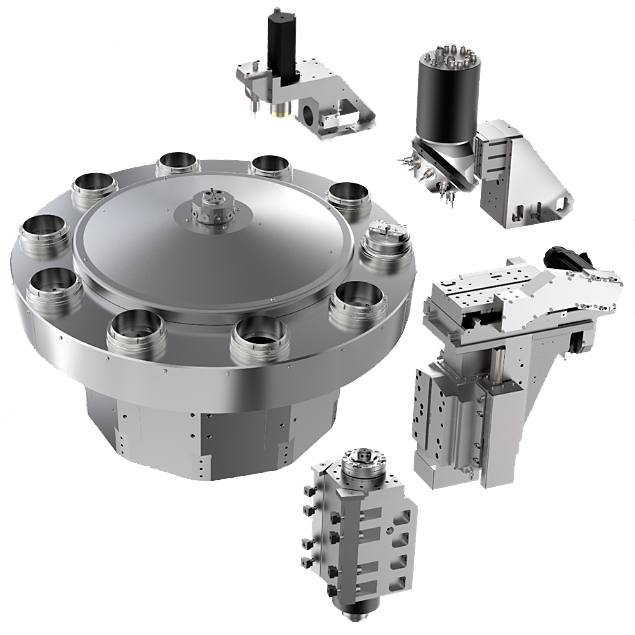

Rotary table

The rotary indexing table is the heart of the system. It enables fast and precise positioning of the workpieces through the rotary movement. By indexing the table, several workstations can be involved in a production process without having to transport the workpiece manually.

A rotary indexing table usually consists of a rotatable plate on which the workpieces are held. This plate is driven by a drive motor and can rotate at different speeds. Our two variants differ as follows:

Drag plate (left). The rotating plate lifts off together with the clamping with integrated workpiece and settles on the next table position. By placing it in the zero point clamping system, we create a clean transition with a highly accurate plane and parallelism.

Indexing table with hirth (right). The hirth-toothed rotary table offers a somewhat different model. Here, the clamping is firmly connected to the rotating plate. The interlocking of the gear rims results in highly accurate contact surfaces.

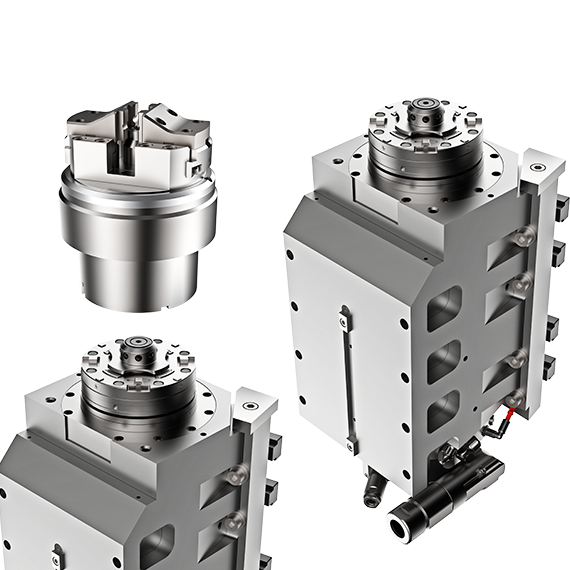

C-Axis

C-axes can be used either as a separate unit or as an integrated component in a machine, and can be equipped with various controls and drives. They enable high positioning accuracy and allow machining operations to be carried out quickly and precisely, resulting in higher productivity and quality.

Our two variants of C-axes (intended for the drag table) give the possibility to either index the clamping together with the workpiece to the desired position (imo-sat) or to let the clamping rotate up to 8'000 rpm (imo-rot). The zero point clamping system offers the absolute precision of ± 1 µm and is integrated in the clamping.

In addition, we have a locking or unlocking/unlocking unit where you can clamp only or clamp and release (e.g. to be able to turn the part on a station).

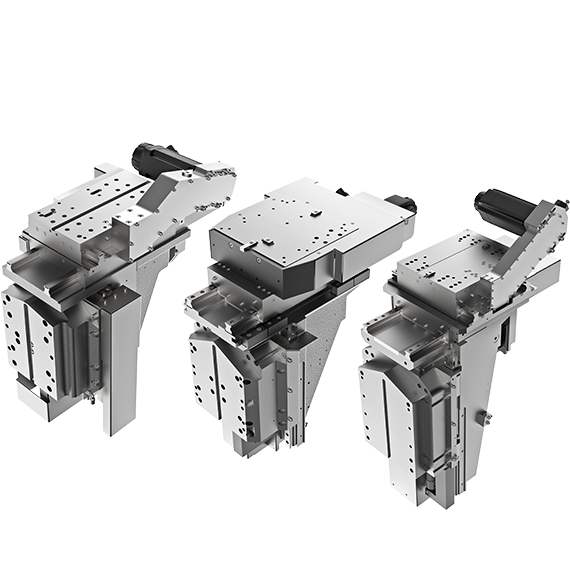

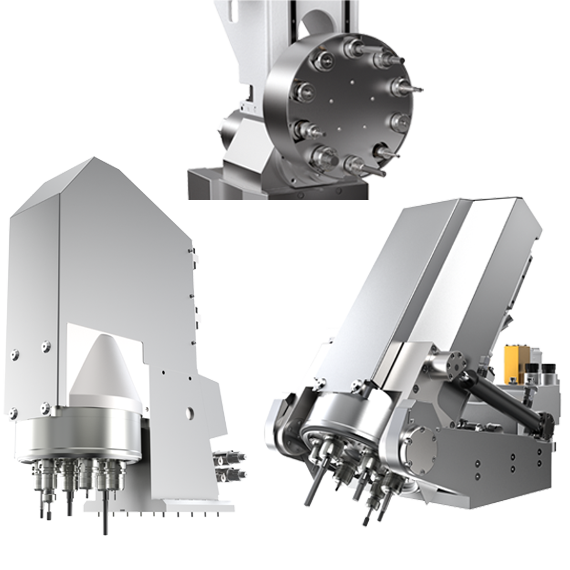

Machining units

With the three different standards of machining units, we cover 90% of the applications. The X, Y and Z axis movements and the wide traverse paths allow an enormous variety of small to medium-sized parts to be produced.

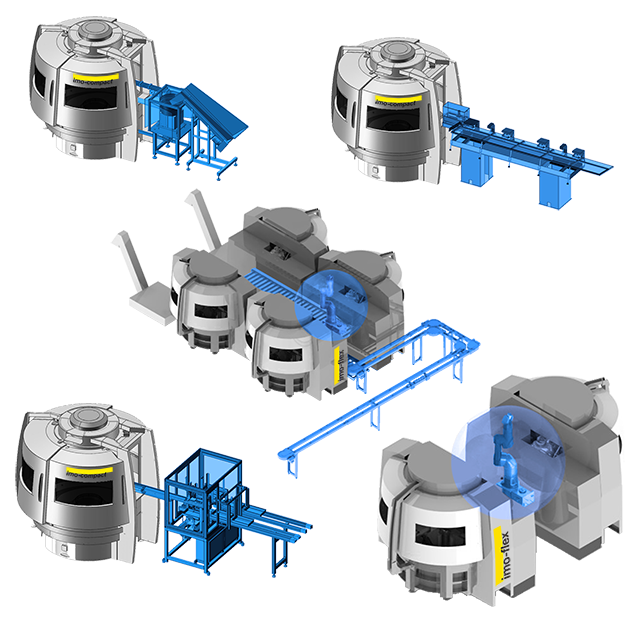

Modularity

Thanks to our modular design, we can integrate the different variants of rotary tables, C-axes and machining units in every imo system. The superstructures are usually tailored to the respective customer requirements. From one to three spindles to a tool changer and much more, we have the technical delicacies. Of course, always in consideration of the cost-benefit ratio.

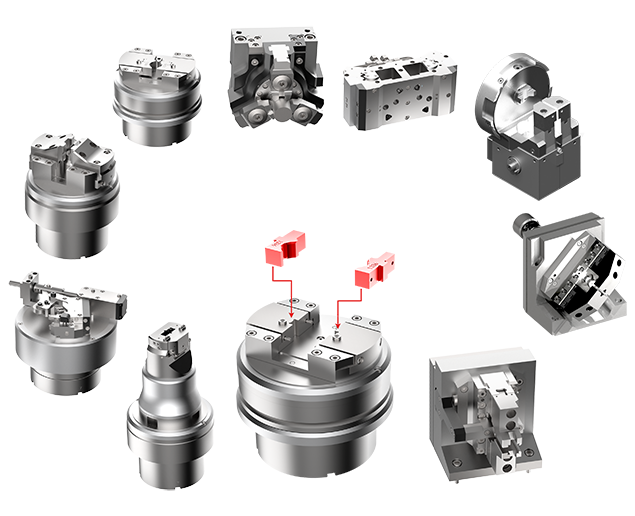

Clamping systems

We have a large selection of different clamping systems. Due to the individuality of the parts and our know-how, we can offer you the best possible solution so that the parts are clamped with high precision.

Special assemblies

Through our various special assemblies, we can supply you with the suitable products. The latest technologies of tool changers such as the imo-TCD, -TCF or our swivelling A-axis and our tool magazine enable further interesting aspects with regard to the system composition. This can extend the service life of systems and machines and increase efficiency and reduce downtimes.

Loading and unloading logistics

We offer various options for loading and unloading logistics. Parts can be fed from the bar, by load handling, robot or manually. With the imo-flex, several machines can also be linked together so that additional systems can be easily added if there is a greater demand.

_3840x1200-2.jpg?width=3840&height=1200&name=Imoberdorf-Standbilder-aus-Film---KMU-Trailer-2019-(0_06)_3840x1200-2.jpg)

News from our industry

Unmanned manufacturing is now a reality

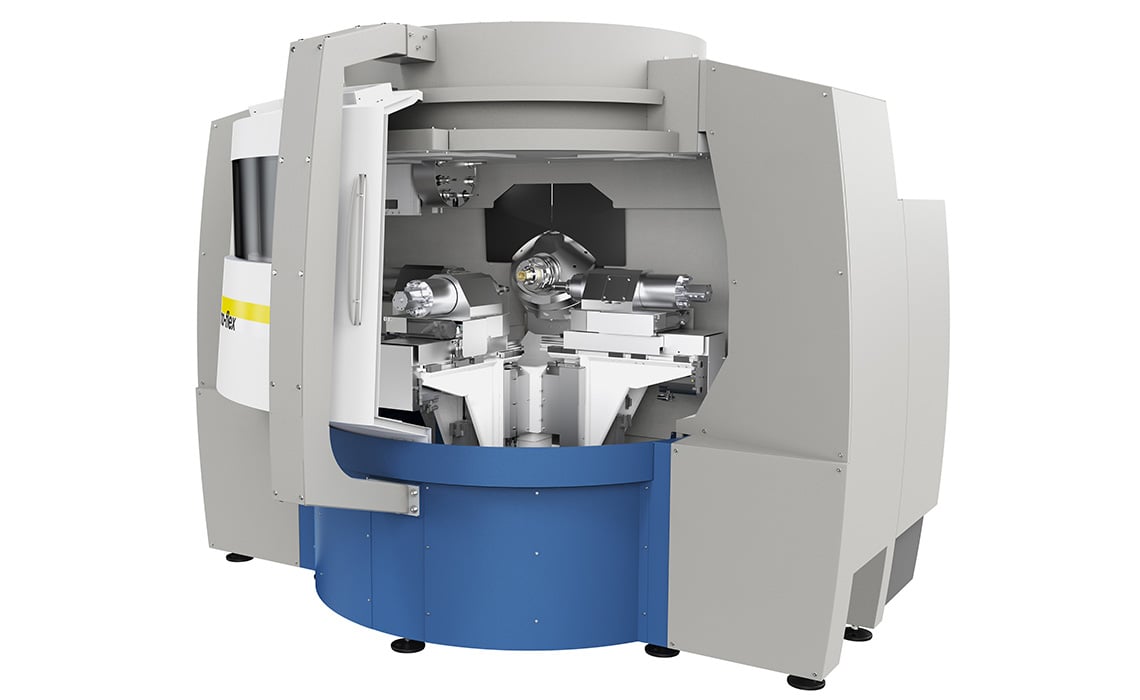

Our new flagship "imo-flex"

-1920x910-HG_Weiss-Banner-Haupseite_1140x700.jpg?width=1140&height=700&name=NEU_2023_01-(63043-821_Werkzeug_1)-1920x910-HG_Weiss-Banner-Haupseite_1140x700.jpg)

Flexible solutions with high accuracy and dynamics

You might also be interested in

Production solutions

Discover our wide variety of products.

Industries

Discover the industries in which our systems are used.

About us

Discover what characterises us as imoberdorf AG.

Career

Discover the career opportunities with us.